ABOUT US

Nile Li-Cycle

NILE Limited is one of India’s largest Lead Acid battery recycling companies, with over two decades of experience in this field. With annual sales of US$ 100mn/INR 700 crores, and a production capacity of 105,000 tons of finished Lead and Lead Alloys, Nile is one of the foremost suppliers of key battery raw materials to some of the largest battery manufacturers in India and South East Asia.NILE has two ISO 9001 and 14001 CERTIFIED state-of-the-art Lead recycling plants, and these are located in proximity to the major cities of Hyderabad and Tirupati/Chennai. Nile Li-Cycle, a fully owned subsidiary of Nile Limited uses patented processes to recover maximum value from spent Lithium-ion batteries. We address the critical need for safe, environment friendly battery recycling. At Nile Li-Cycle, we enable cost-effective battery recycling and help to drive technology and prosperity in India.

TECHNOLOGY THAT IS SAFE AND SUSTAINABLE

Nile Li-Cycle uses a combination of mechanical and hydrometallurgical resource recovery technologies that have been developed for recycling Li-ion battery waste. These licensed/co-developed and patented processes are the validation of years of R&D efforts by NILE and its technology partners and prosperity in India.

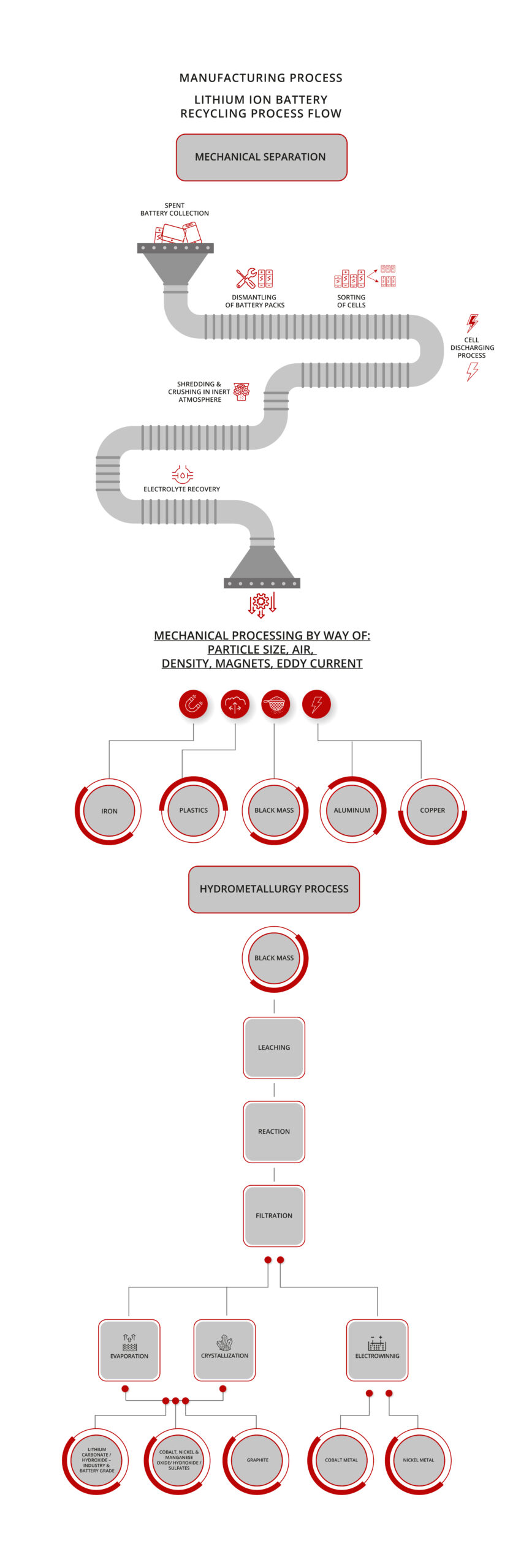

MECHANICAL SEPARATION

All kinds of lithium-ion batteries are collected, then discharged, sorted, shredded and crushed in an inert and enclosed environment to ensure there are no fumes and dust released into the atmosphere. Then, through indigenously developed efficient means of mechanical separation via particle size, density and magnetic properties, the majority of the metallic material is separated from the anode and the cathode material. This remaining fine black powder is called black mass, and it forms the input for the next stage, i.e. Hydrometallurgical processing.

HYDRO METALLURGICAL PROCESSING

Nile Li-Cycle then uses Hydrometallurgy, which involves various processes like leaching, reaction, filtration, crystallization etc. to turn black mass into several industries and battery-grade end-products for reuse in various industry and battery applications.

SAFE AND SUSTAINABLE TECHNOLOGIES AND PRODUCTS

Our environment friendly solution for treating end-of-life Lithium-ion battery waste will help create an alternate supply chain for critical minerals and compounds. This will help India meet the demand for key battery raw materials. Our proprietary technology allows for safe processing of all Lithium-ion batteries whilst significantly cutting down on GHG emissions and waste sent to landfill, thus providing a viable end-of-life pathway for all Lithium-ion batteries.

Our Team

MR. VUYYURU RAMESH

Chairman of NILE Limited.

Mr Vuyyuru Ramesh is a graduate in Mechanical Engineering from IIT, Madras. He also holds a MS from the University of Wisconsin, USA, and an MBA from the University of Toronto, Canada.

MR SANDEEP VUYYURU RAMESH

MD. Nile Limited and Director, Nile Li-Cycle Pvt. Ltd.

Mr Sandeep Vuyyuru Ramesh is a commerce graduate and holds an MBA from the Indian School of Business, Hyderabad. He joined NILE Limited in June, 2009 as General Manager of the Lead division.

MR Y. KALIPRASAD

CEO, NILE Limited and Director, Nile Li-Cycle Pvt. Ltd.

Mr Y. Kaliprasad is a graduate mechanical engineer with several management certifications. He is also a qualified lead auditor for ISO management systems.